The Problem

Wayfinding is a tricky thing: for some, it comes naturally and without a second thought. For others like myself, wayfinding is a matter of trial and error (mostly error), anxiety, and frustration. Cell phones have greatly helped people like me, but only insofar as finding a destination, not in truly understanding cardinal direction. GPS is useless indoors. The reliance on a visual display can be a deadly distraction behind the wheel.

Goals

Build Confidence

No Visual Displays

Communicate Cardinal Direction

Inspiration

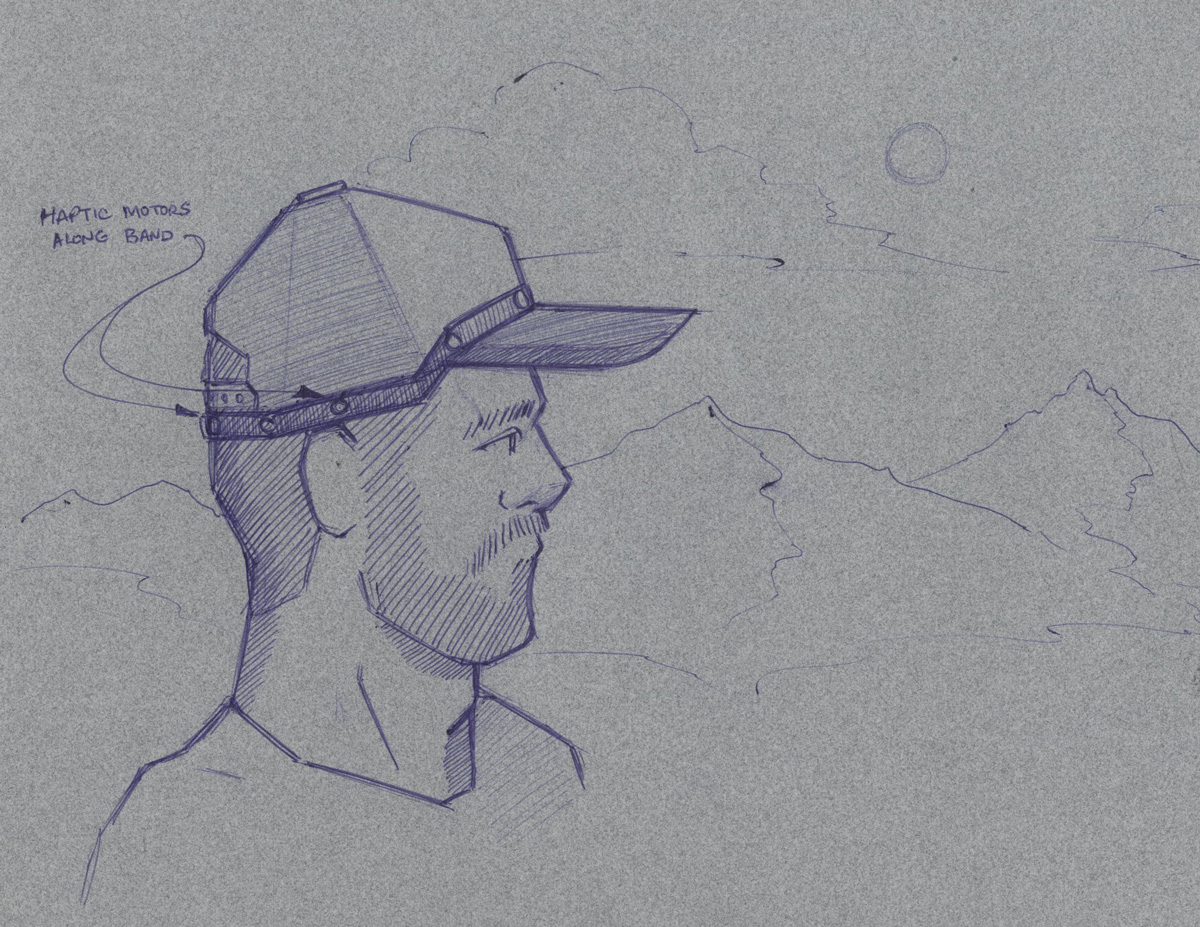

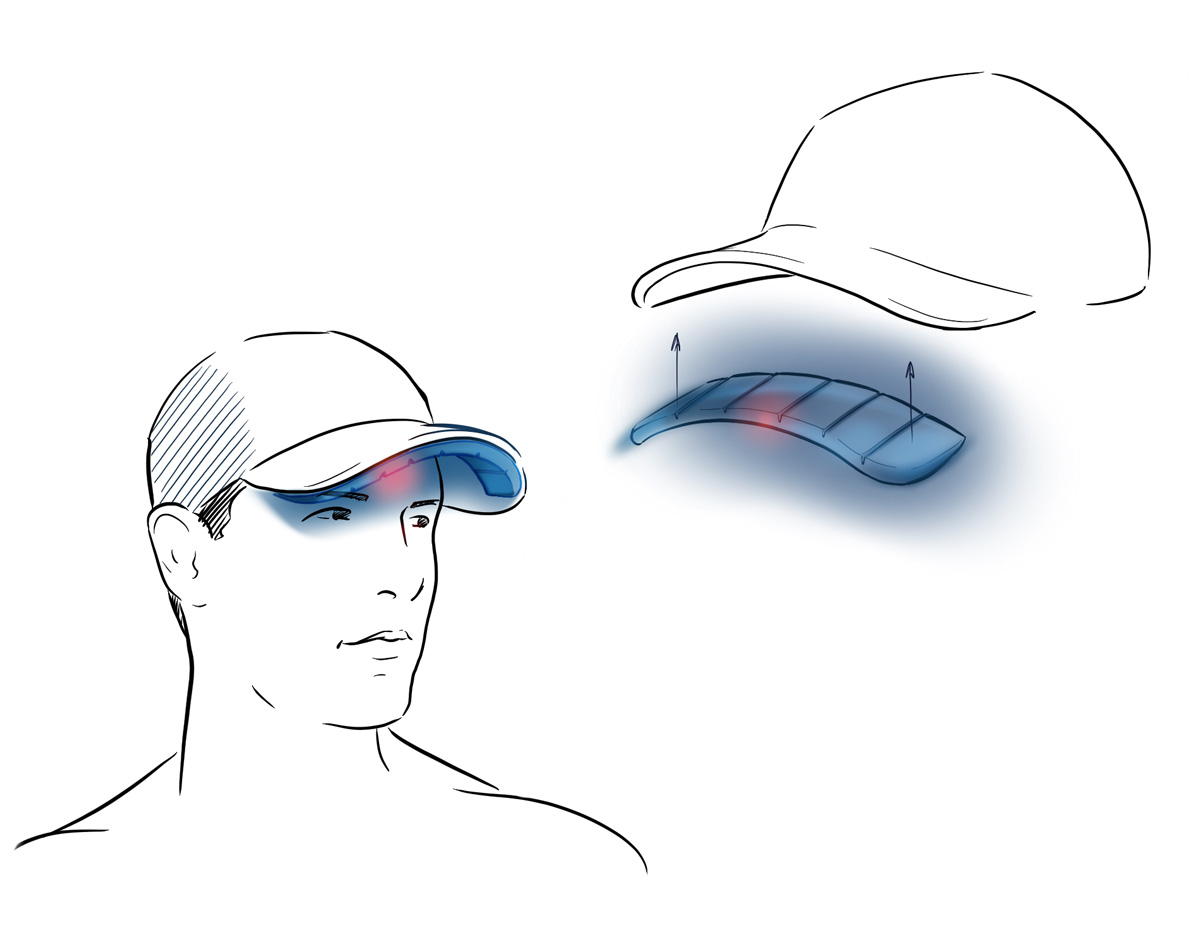

Many species of bird, shark, and ant use magnetoreception to orient themselves by perceiving the Earth's magnetic poles. I realized that we can artificially perceive them by using easily sourced electronics and communicate their direction to the user with vibrating haptic feedback or LEDs.

How It Works

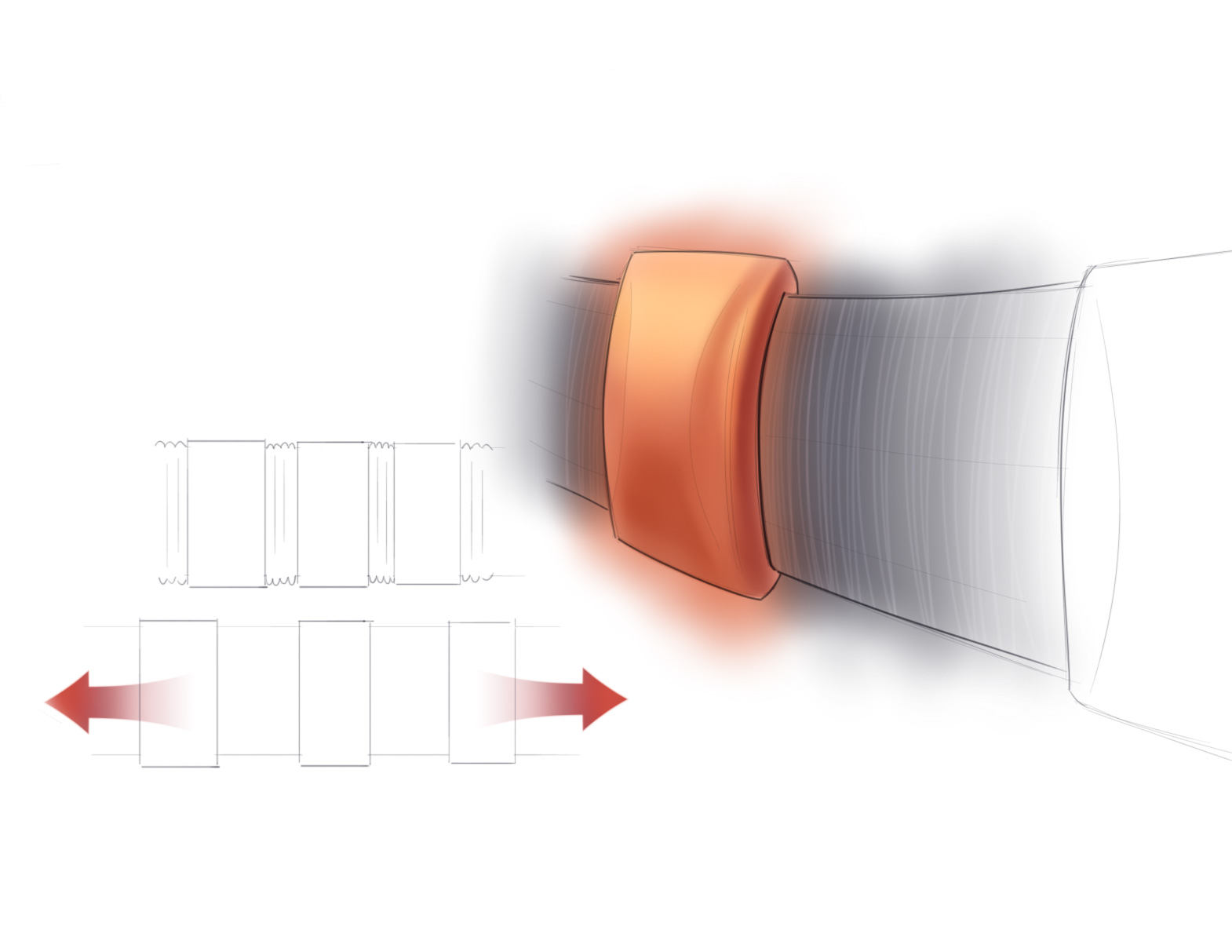

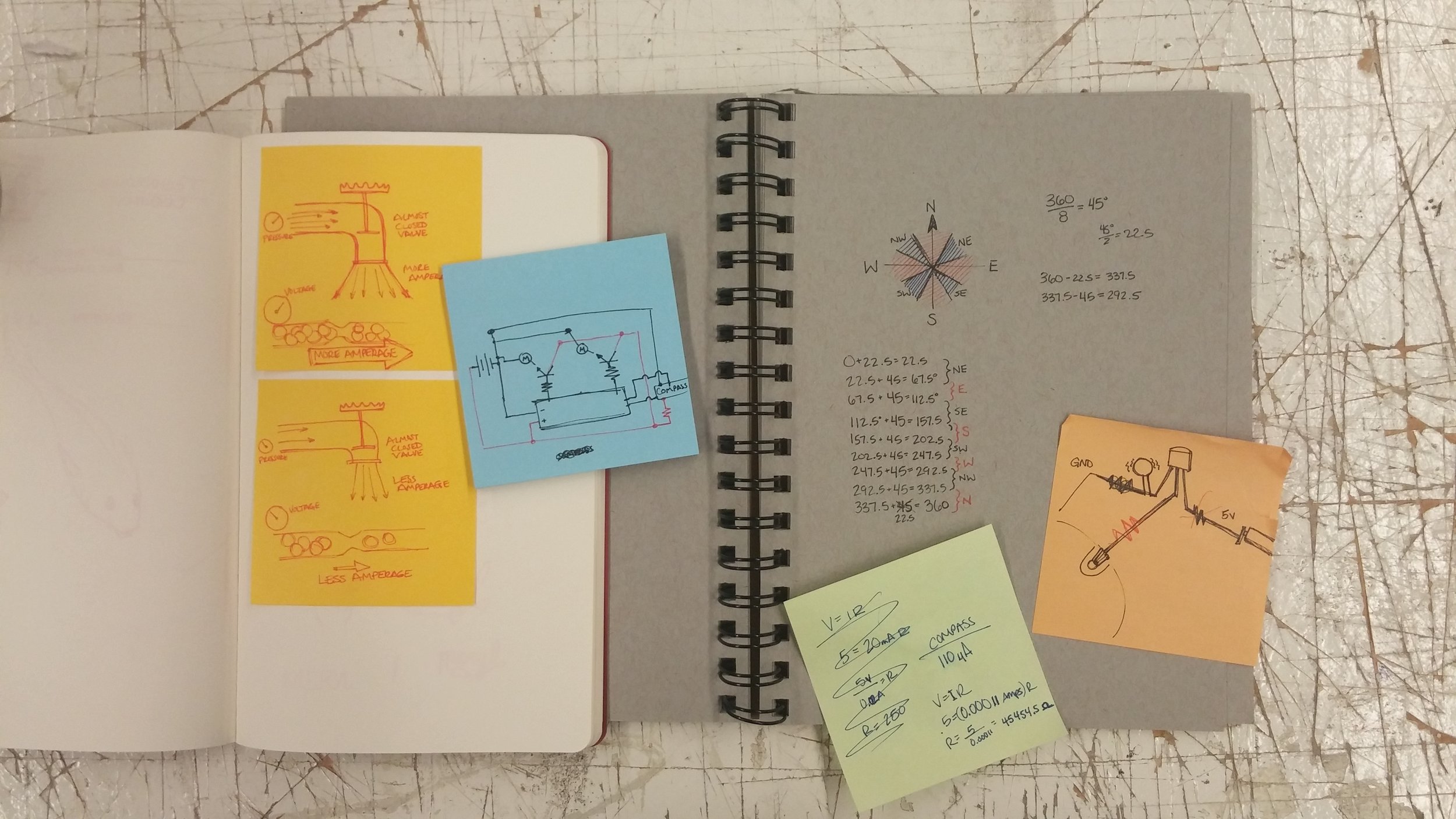

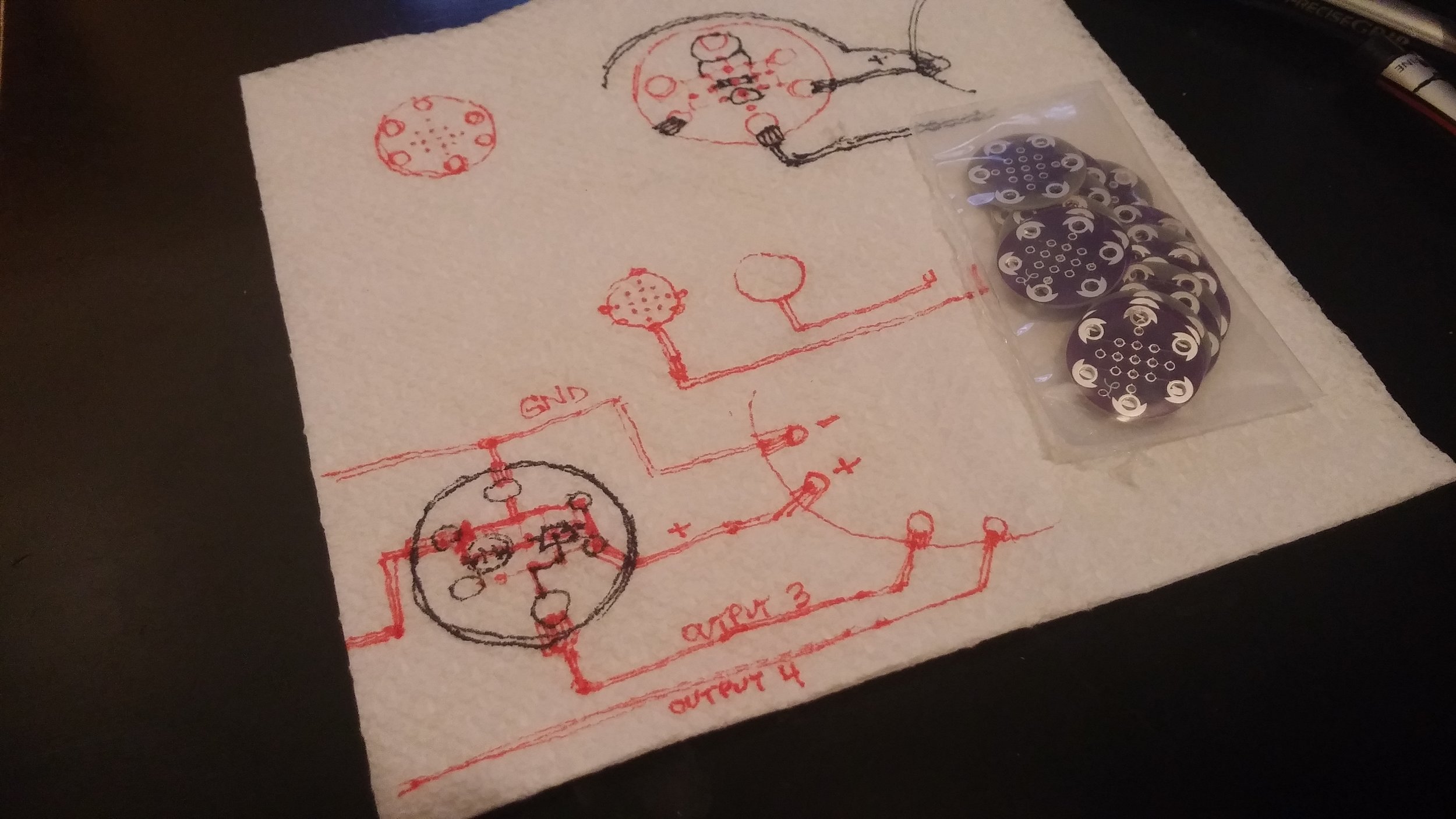

A set of eight vibration motors is worn in a circular array. A magnetometer detects magnetic north. A microcontroller takes the readings from the magnetometer and actuates whichever motor is facing closest to north. The diagram below illustrates how this works.

The green figures show which motor is vibrating relative to north. The red figures indicate which motor is vibrating relative to the user (i.e. where the user feels the vibration).

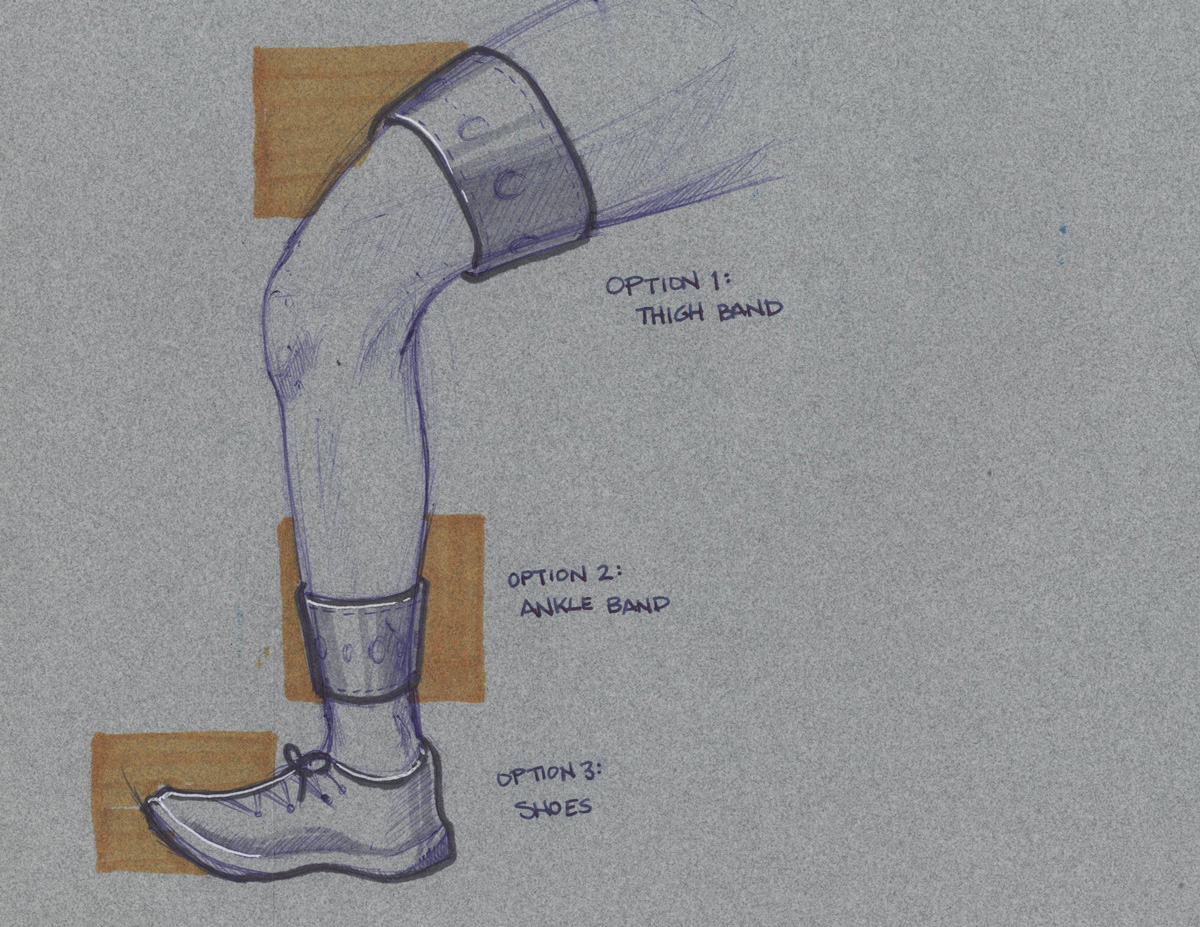

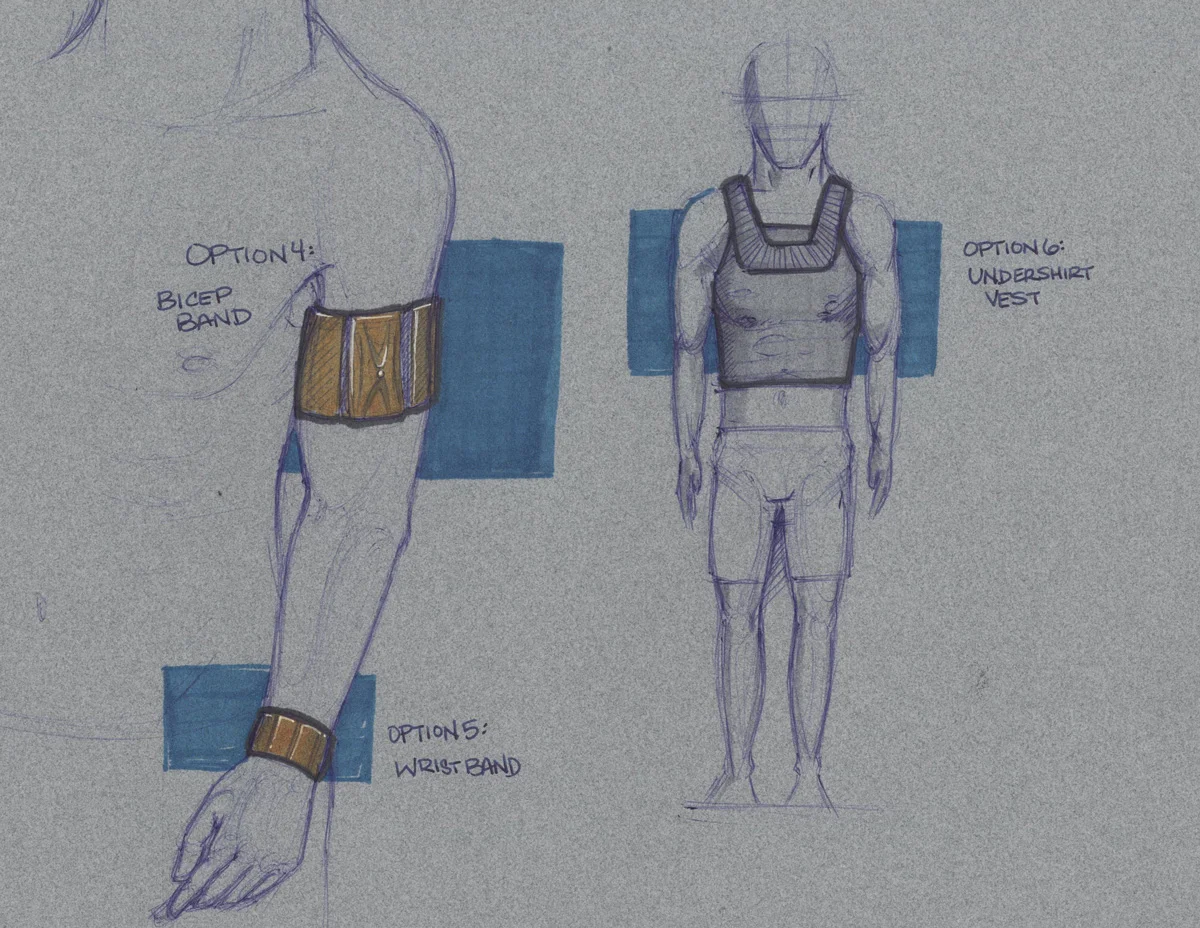

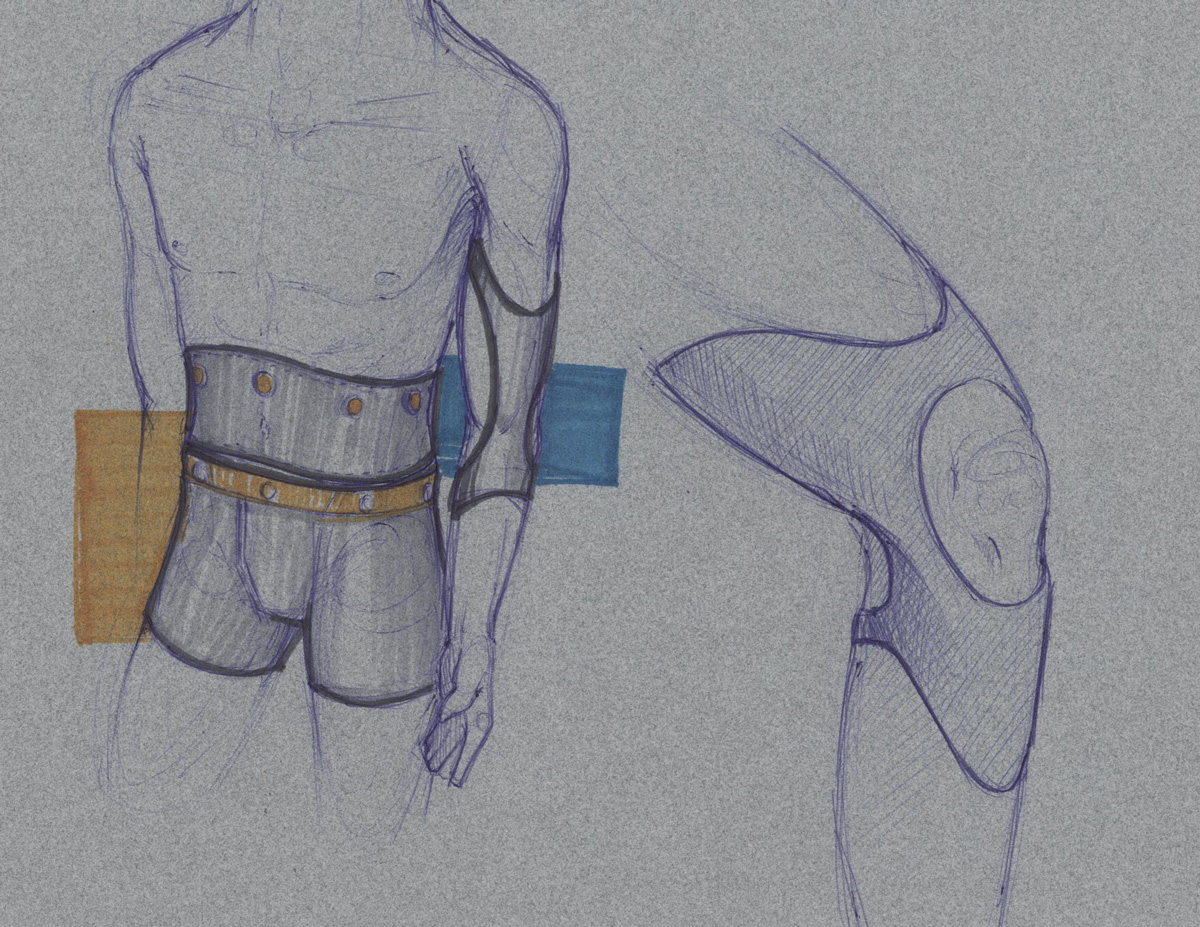

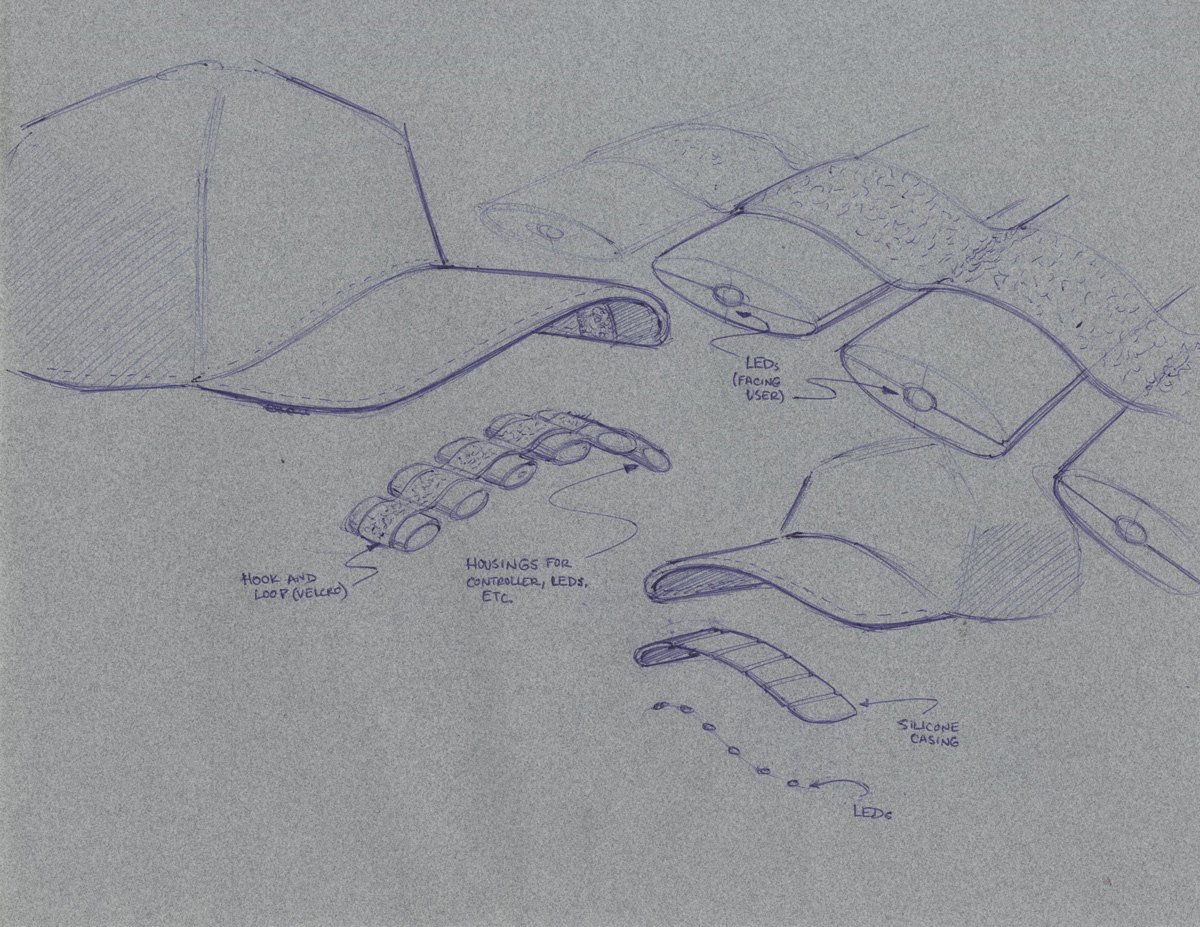

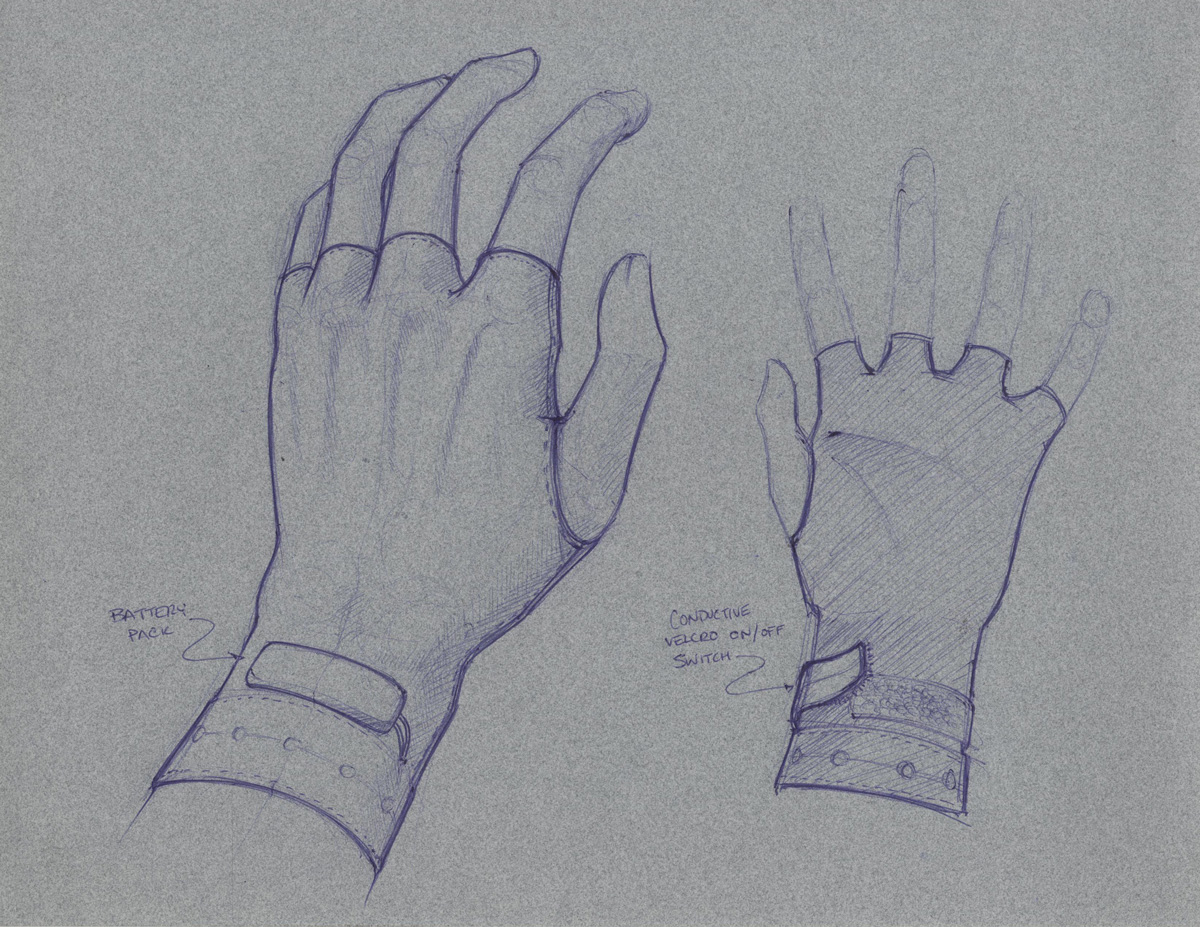

Sketch Exploration (Paper)

Hover over to pause slideshow

Sketch Exploration (Digital)

Study Models

Findings

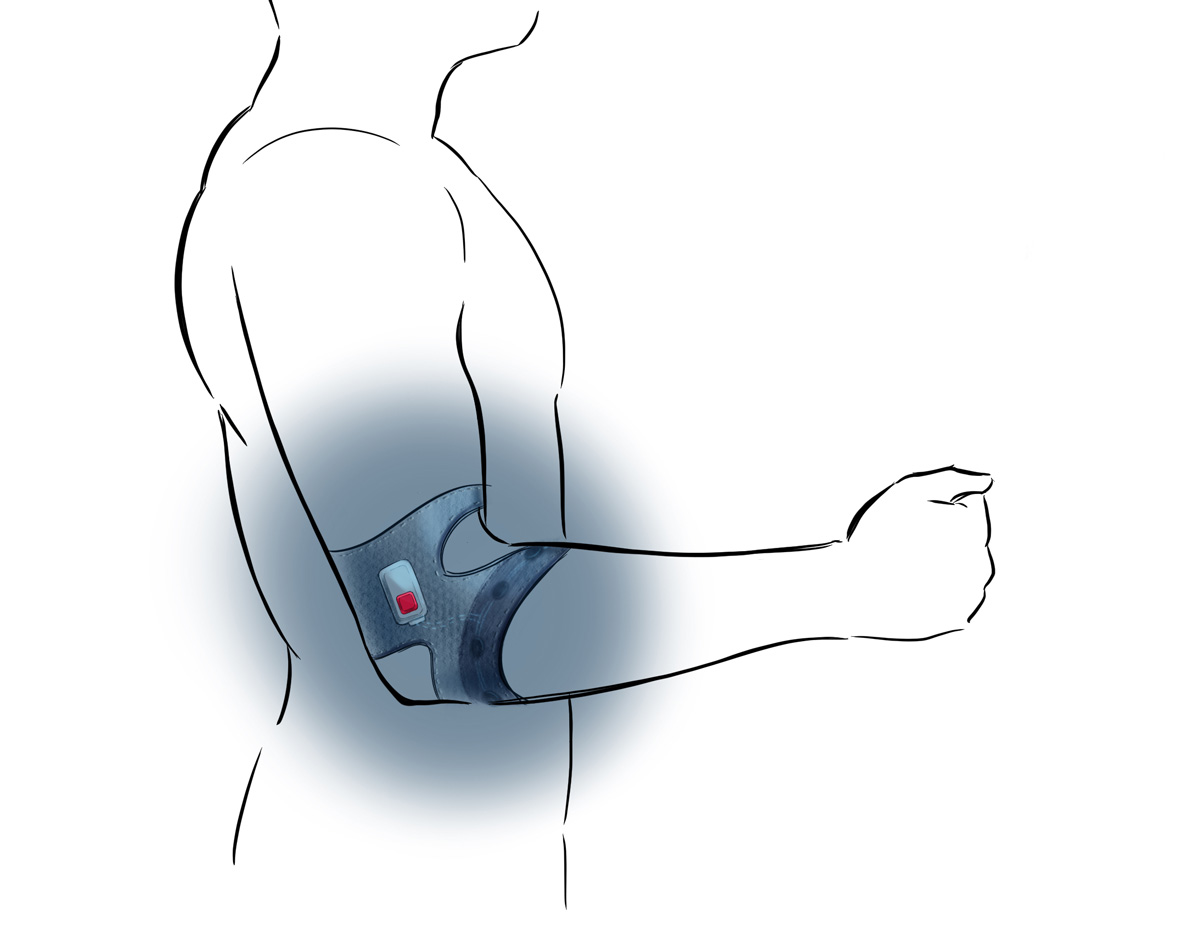

By making a series of quick study models, I documented the most comfortable and uncomfortable places for a wearable device.

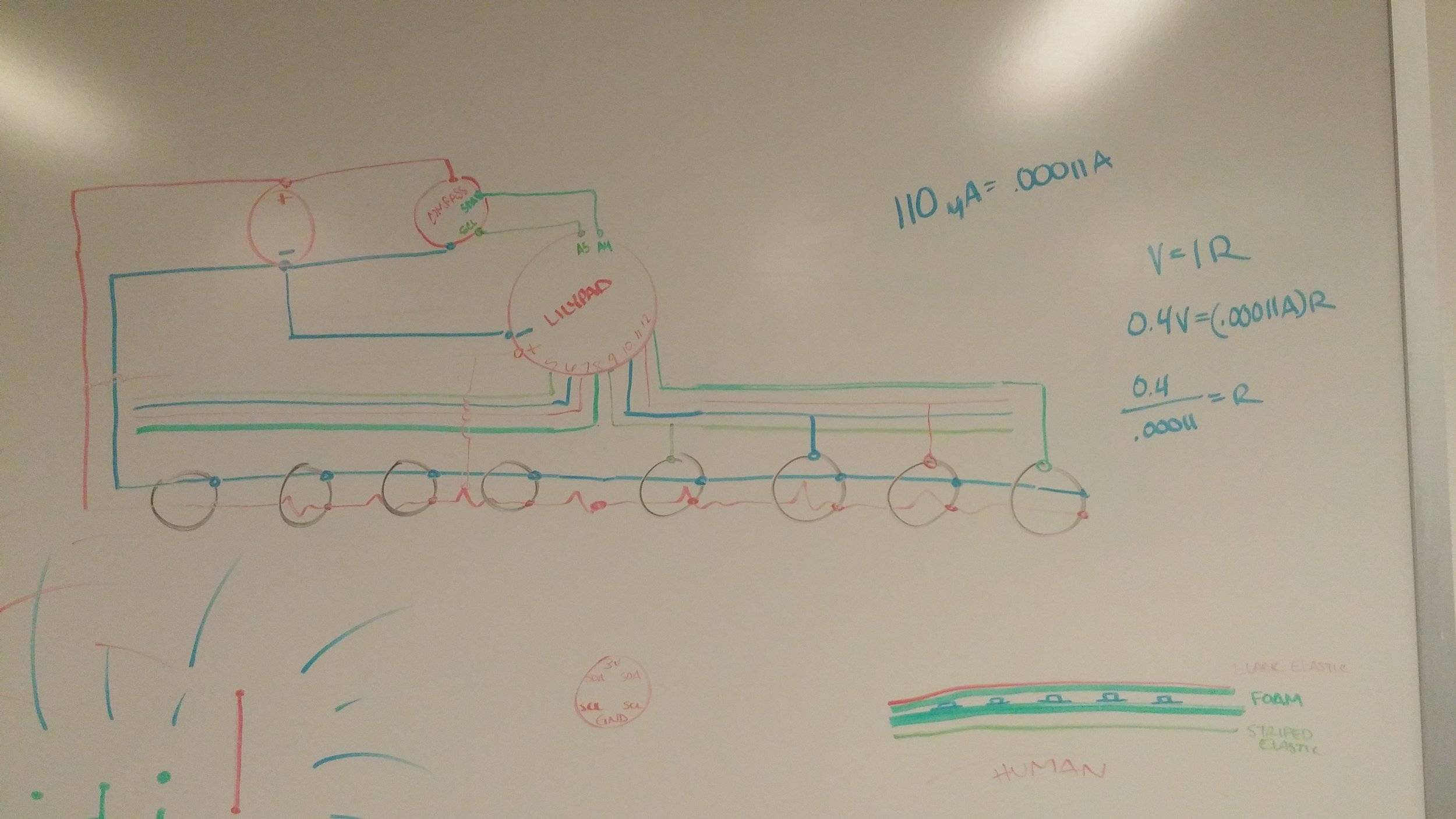

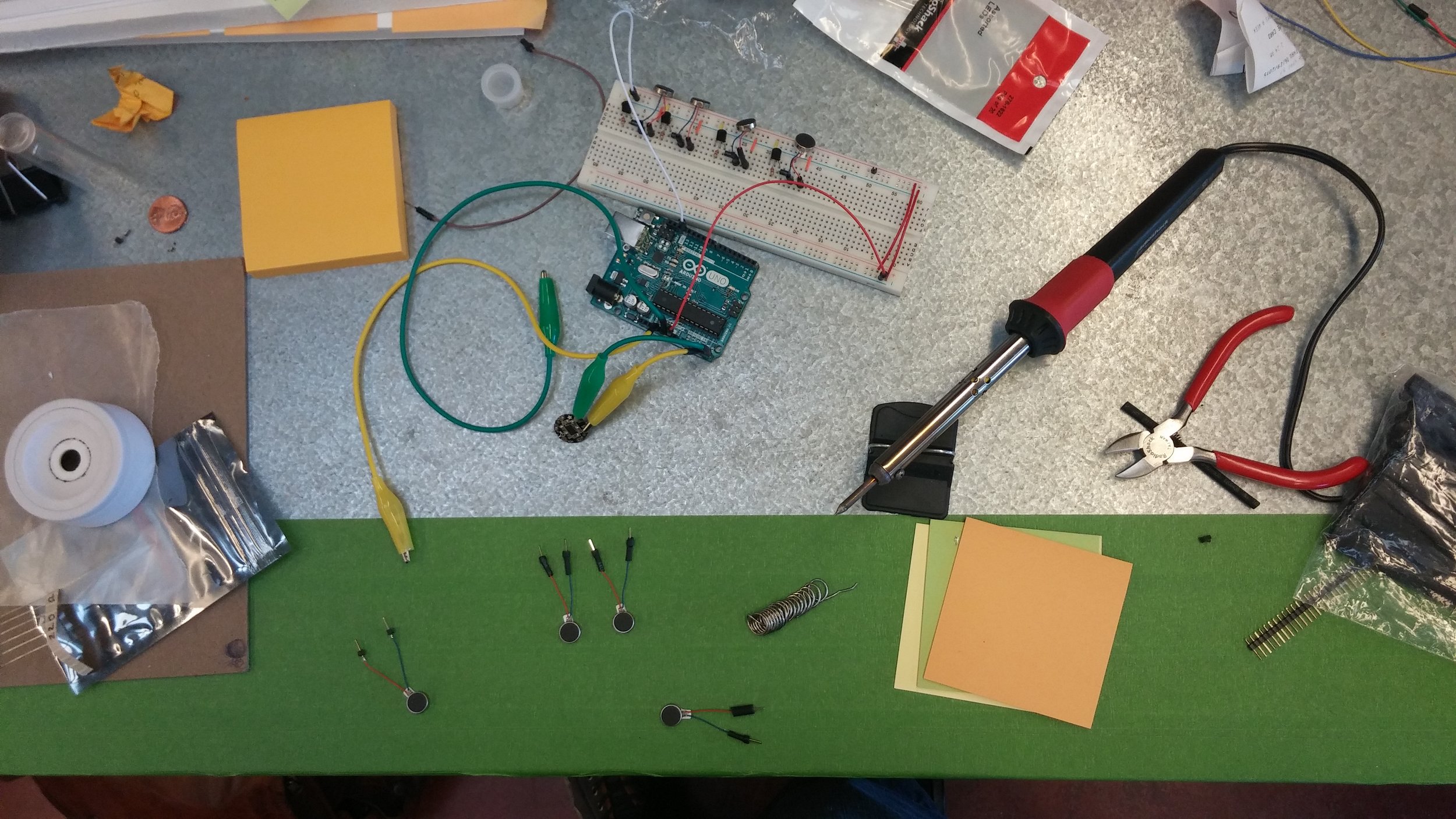

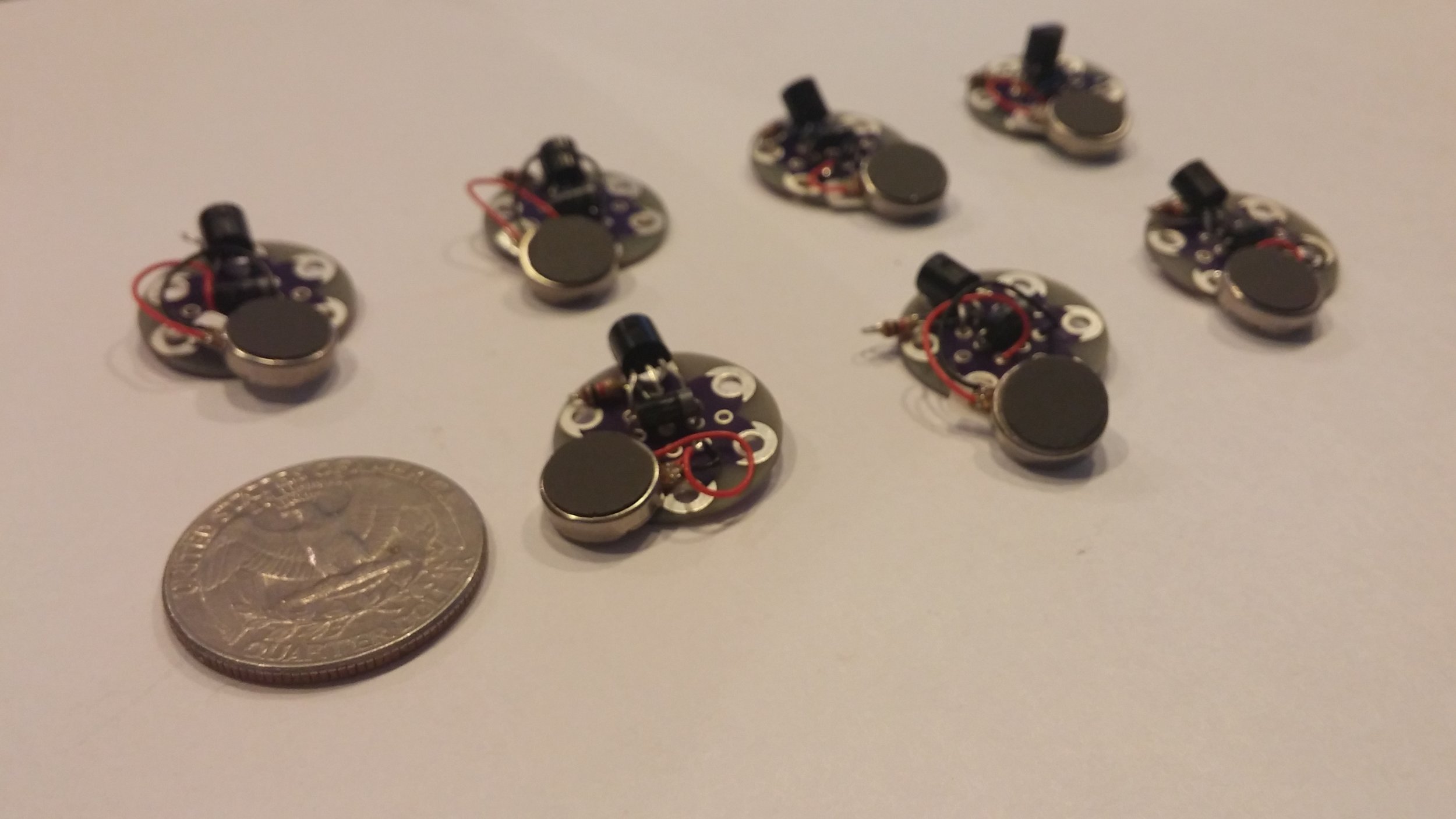

Aside from making study models, I also set out to create a proof of concept. The goal was to prove that it could be achieved using simple circuitry and to gain a better understanding of electronics in general.

The proof of concept was made on a breadboard using an Arduino Uno and cheap electronic parts. I learned how to solder, gained an understanding of circuitry, and learned how to program the microcontroller. After making a fully reactive and functioning proof of concept, I proceeded to create a prototype using sewable electronics and e-textiles. I chose to make a belt despite my study model findings due to scale limitations.

The prototype worked for about 30 seconds before an electric arc caused it to catch fire. Literally. Lesson learned: give ample space between positive and ground leads.

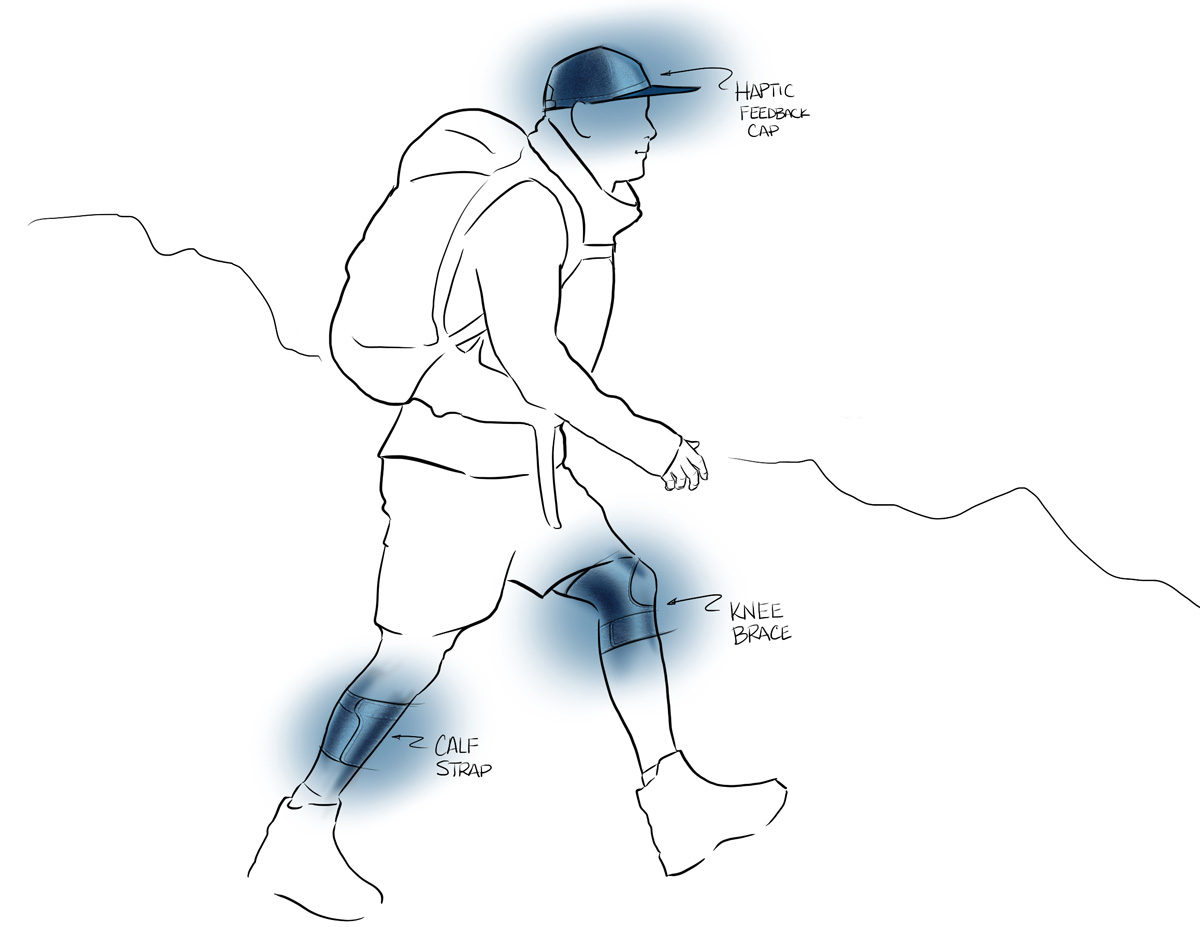

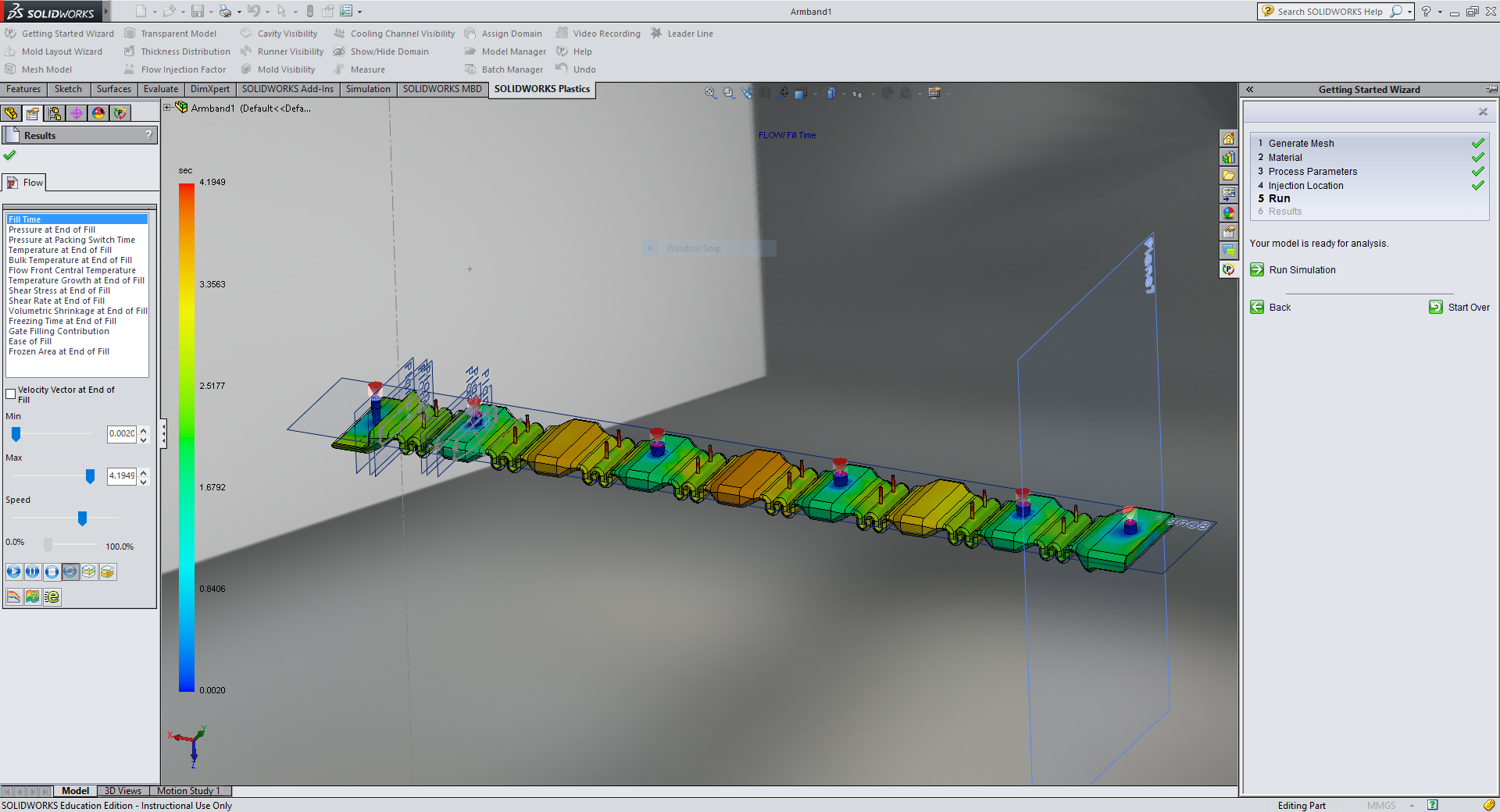

Finalizing the Design

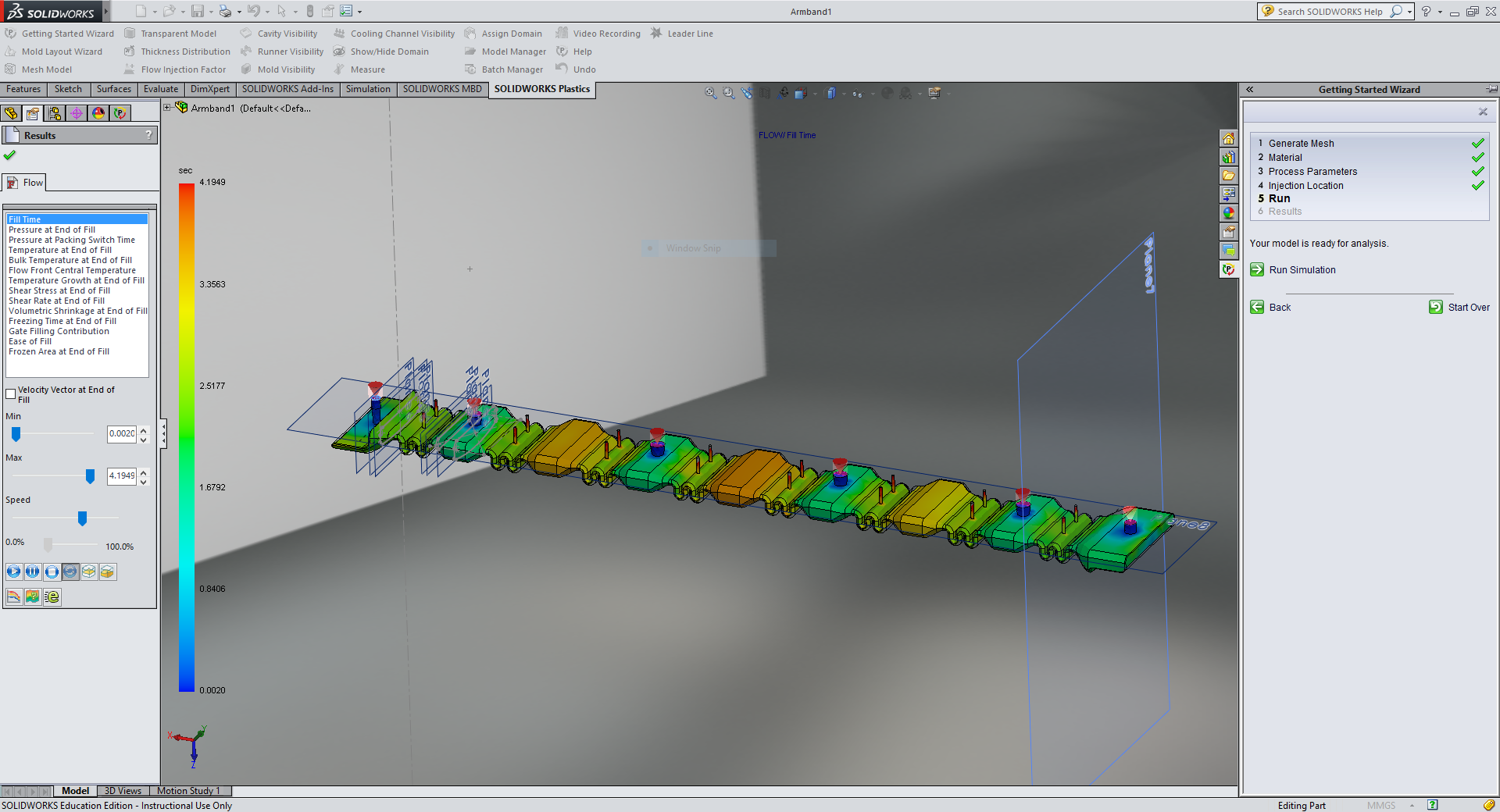

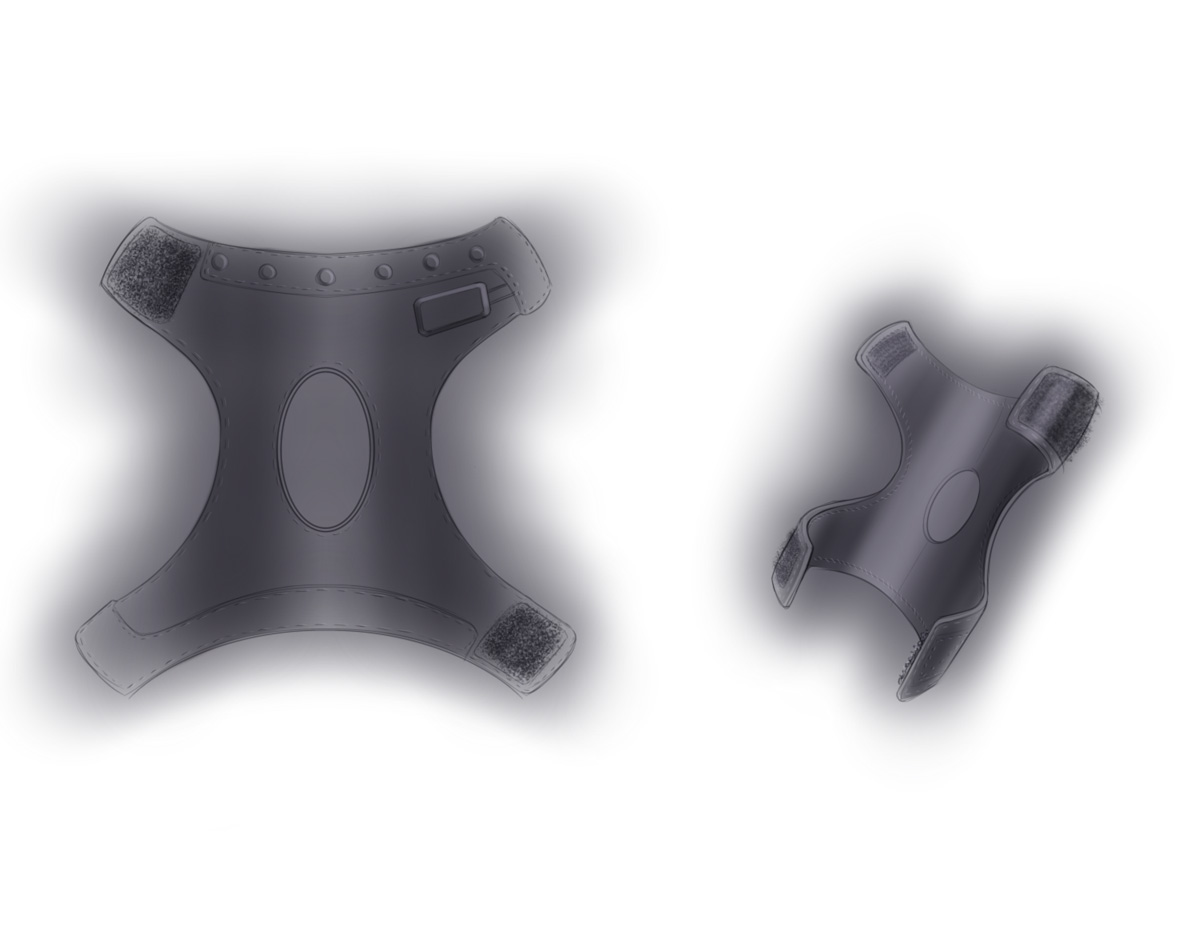

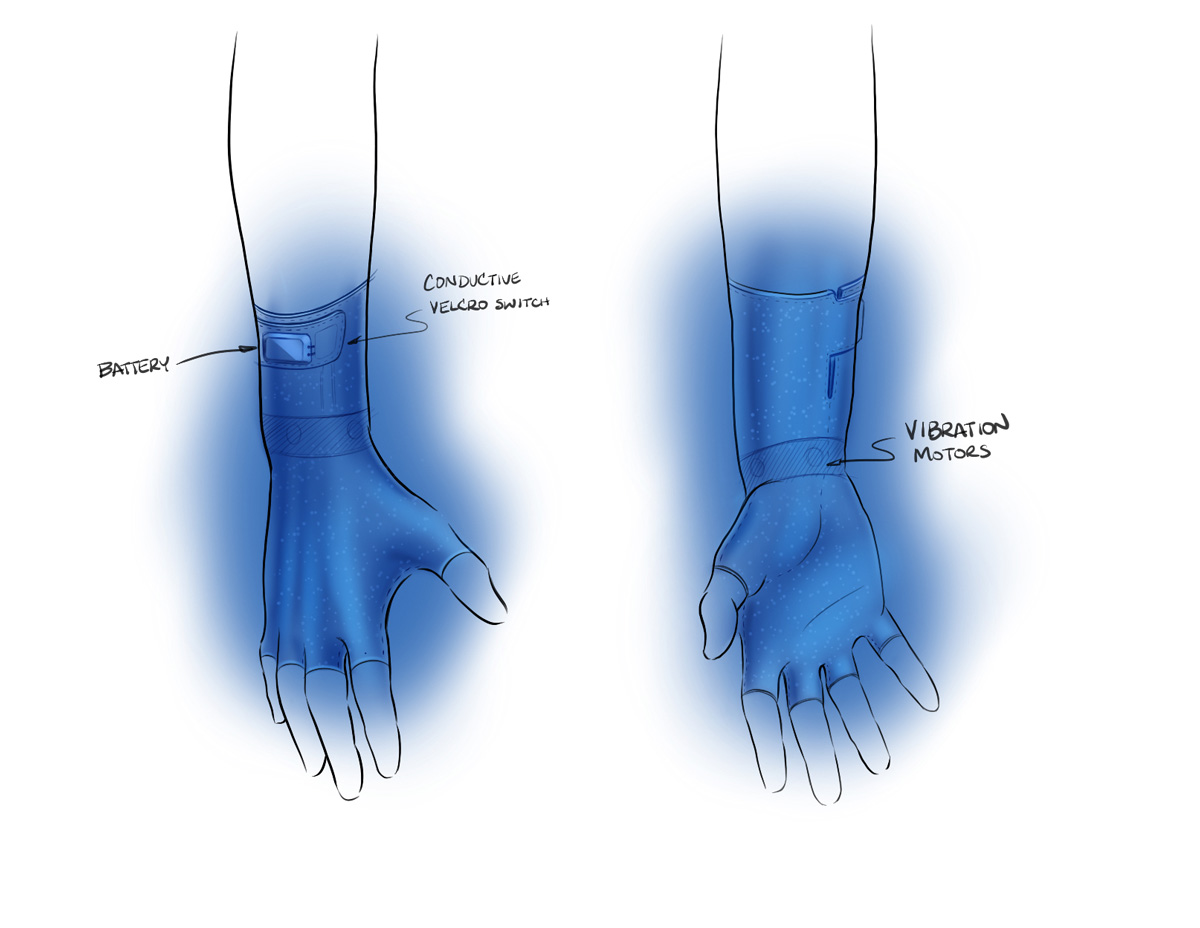

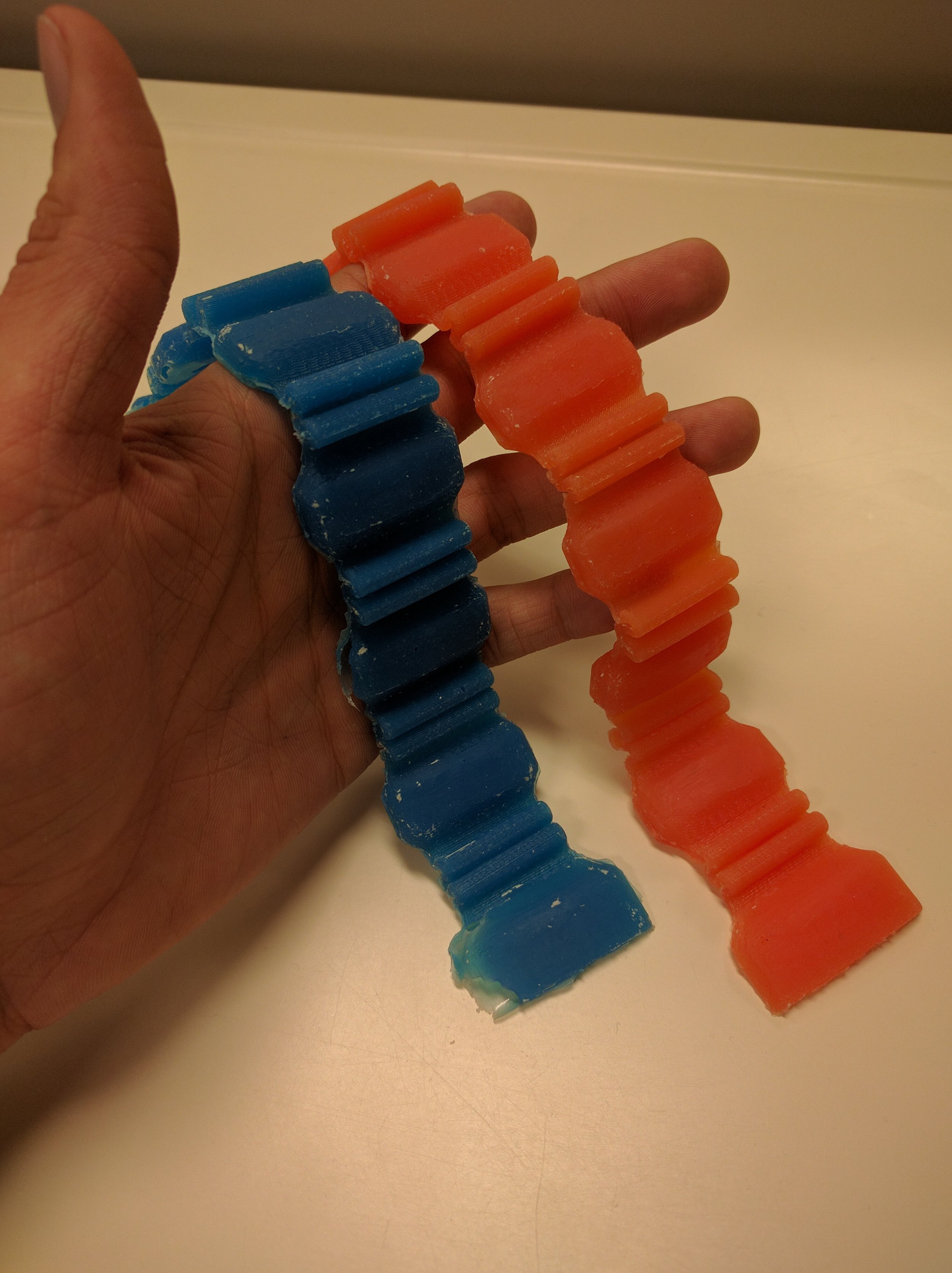

The wearable is a stretching armband or calf strap, worn wherever is most comfortable for the user. The wearable is low-pressure molded in TPE/silicone and houses eight vibration motors, a small microcontroller, a magnetometer/accelerometer, a series of rechargeable batteries, and cables connecting it all together. The band has molded-in pleats to provide flexibility and expandability which account for different limb sizes. Conductive snap buttons are used both to secure the device and to complete the circuit.

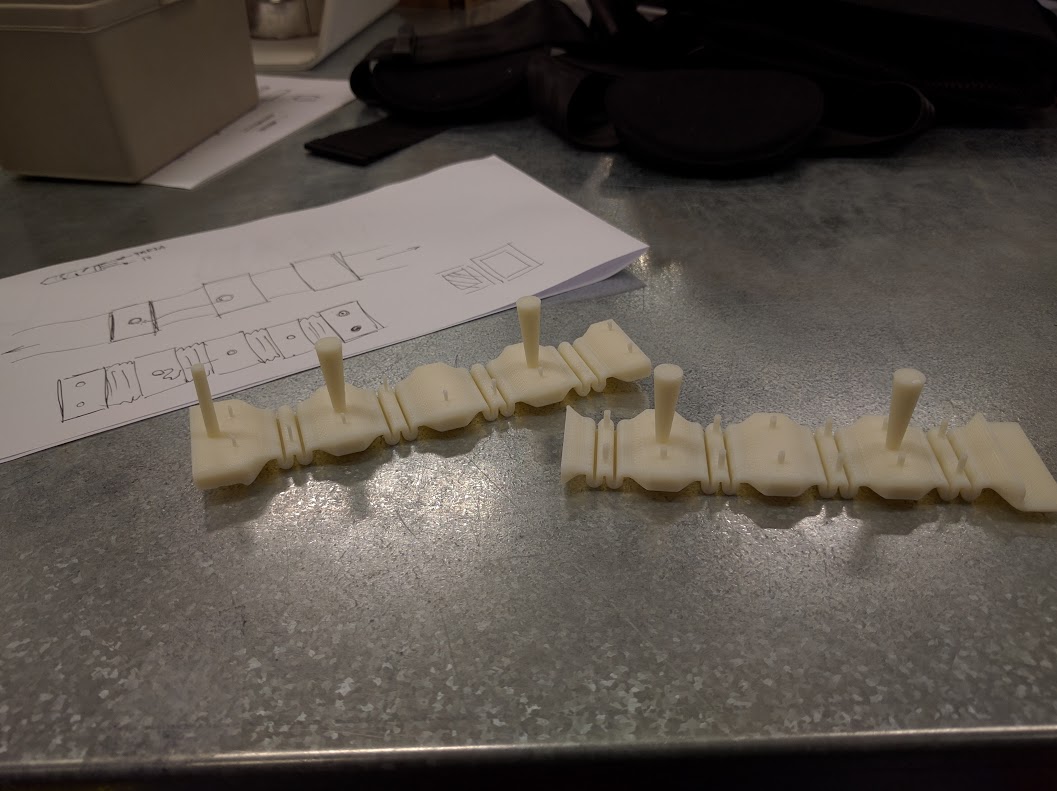

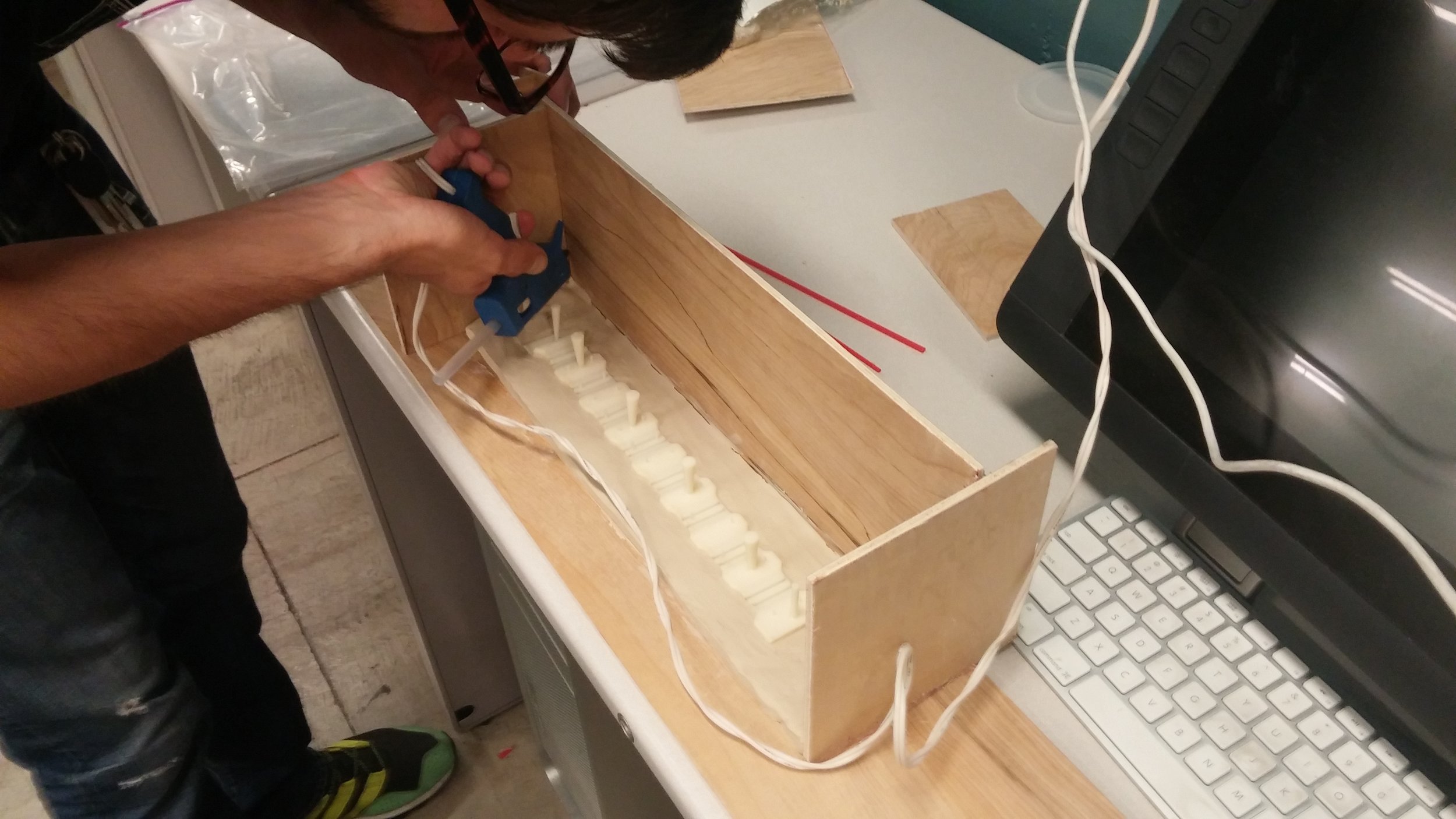

Making a Silicone Study Model

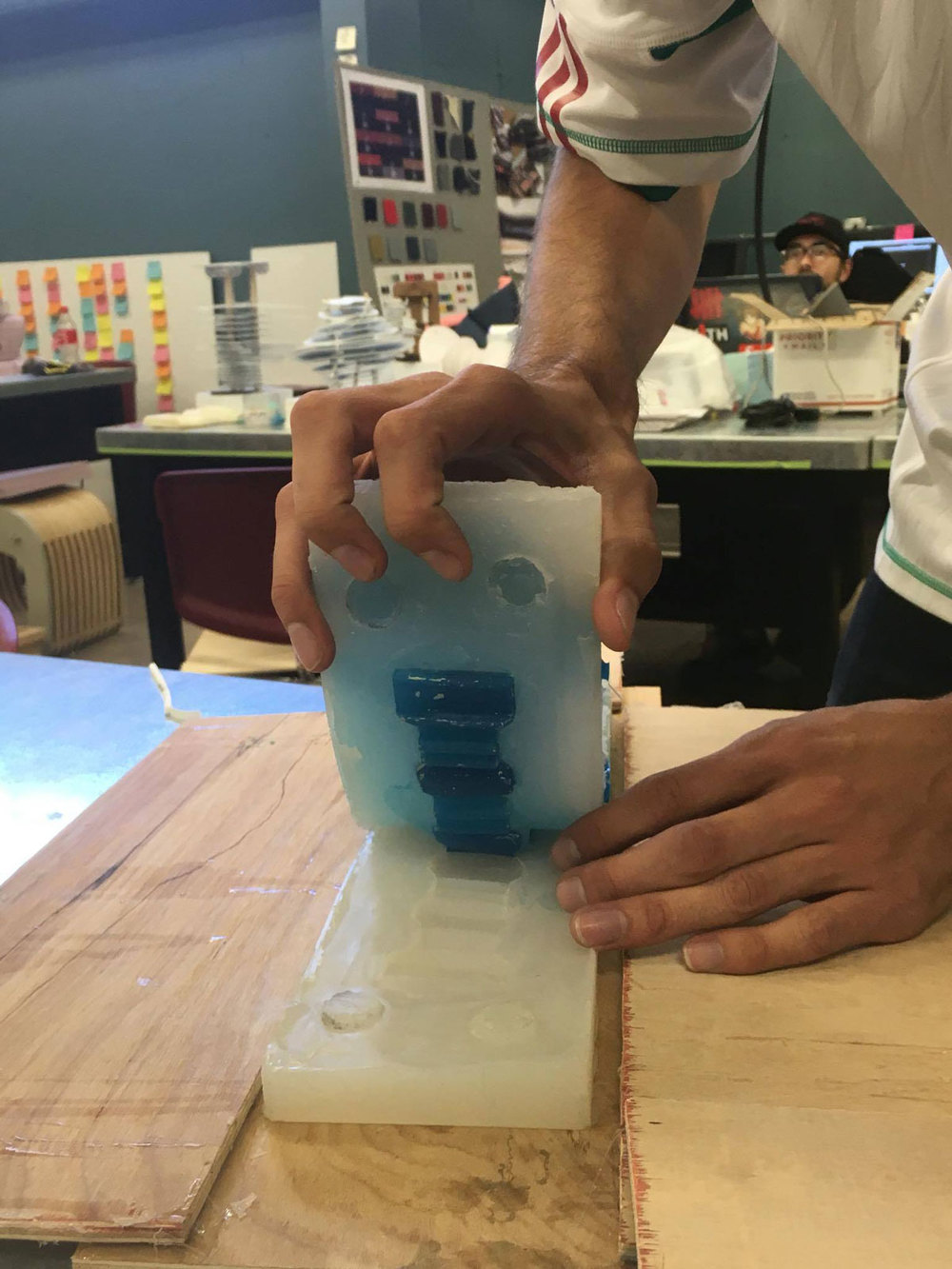

To validate the geometry of the band, I wanted to make a silicone model and see how it would actually expand. This gave me the opportunity to learn a new skill: mold making and casting.

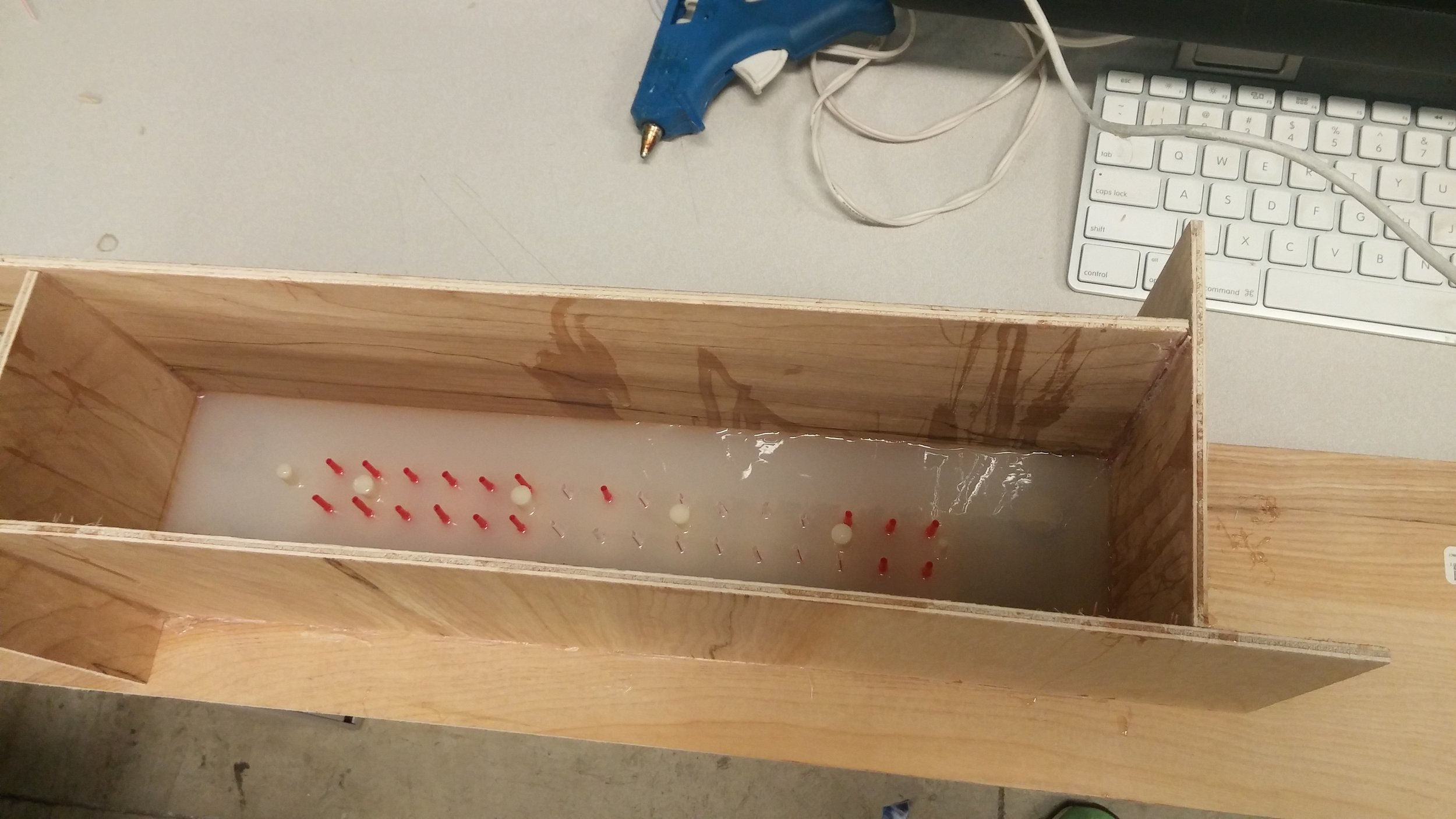

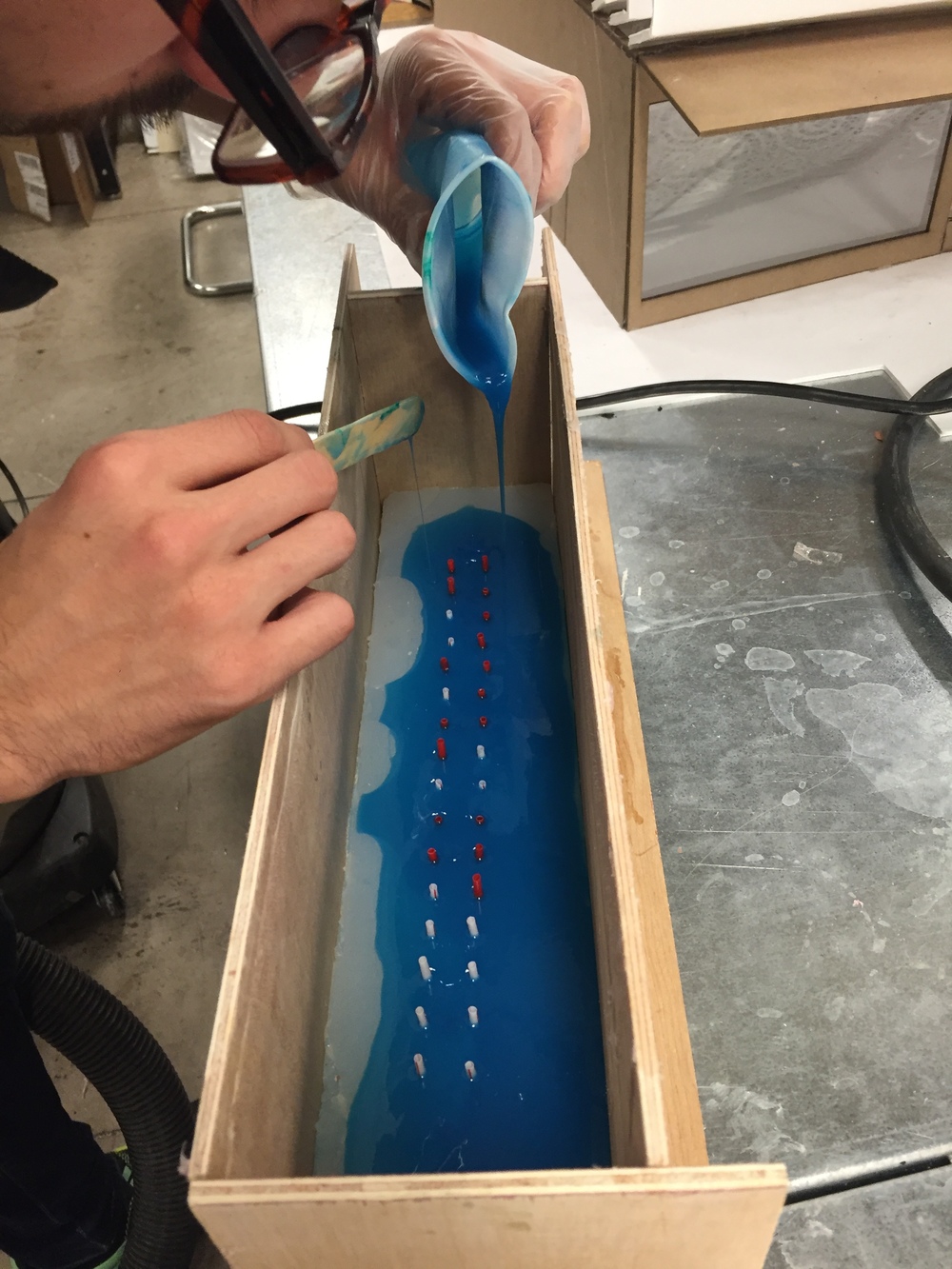

Lessons Learned

When mold flow analysis marks a problem area orange, even if it's "not that orange" and you have a bunch of air vents to help, you should really listen...

Because your model will end up with bubbles in it (see blue band). More sprues were cut into the mold for the second casting (see orange band).

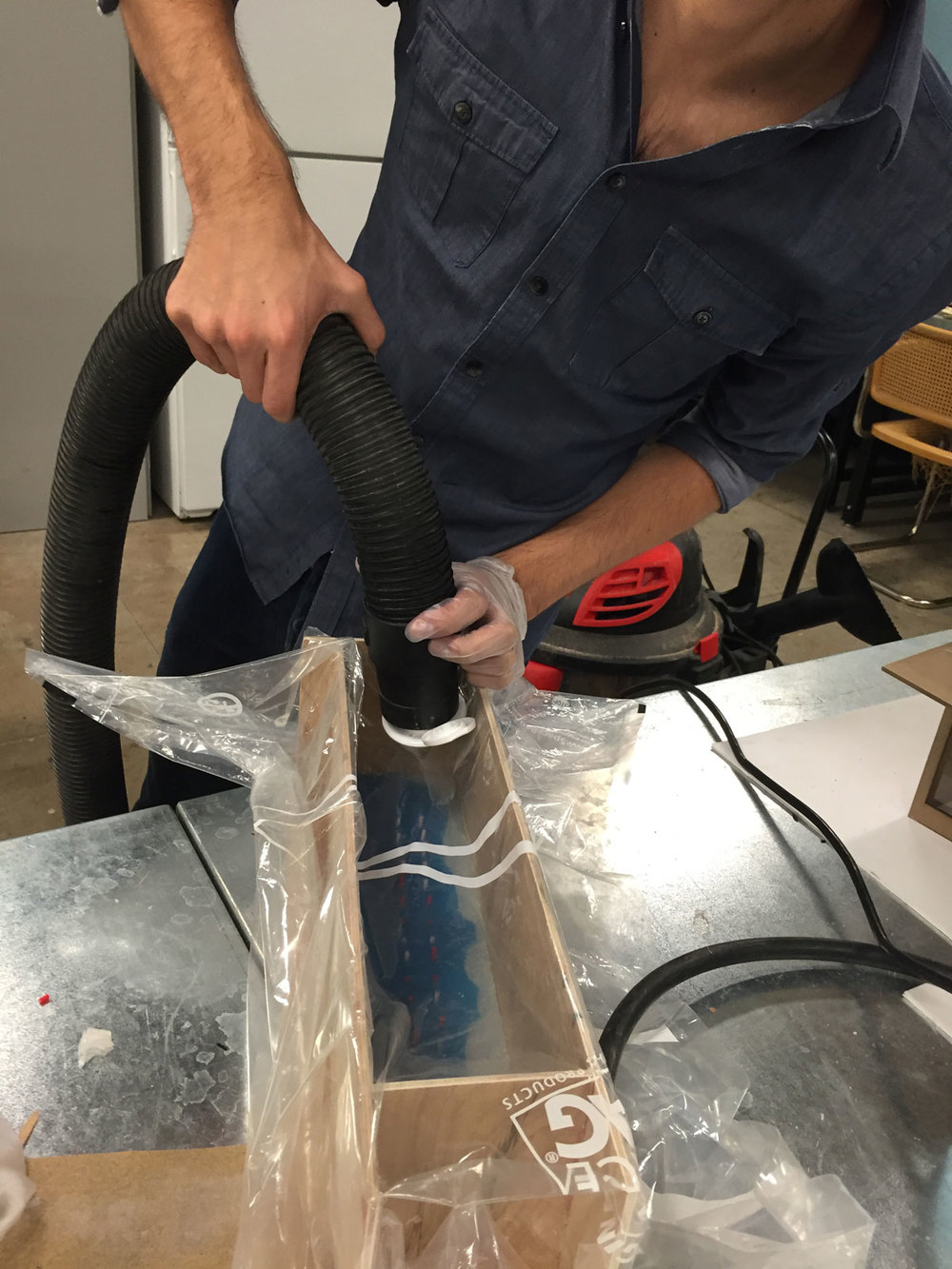

If you don't have access to a proper vacuum chamber and your mold is susceptible to air bubbles, you can always use your mom's space bags and a shopvac to make a....